| Stage 1

Europe follows two key objectives in matter of energy technologies: to decrease the cost of clean energy and to bring the EU’s companies on the first place in the sector of the energy technologies with small emission carbon, sector that is in full development.

Because of the characteristics that it presents ( big specific power, small specific consumption, operating flexibility, etc.) gas turbine groups are more and more used, getting inside the most important fields of economy. We can say that the overall orientation, at this moment, in our country and abroad, is to promote the groups with cycle cogeneration turbine engines in complex industrial installations, to improve their performance as much and customize them for different sectors of the economy. In these circumstances it is usual to give a special attention to research of all the possibilities of improving the operating characteristics.

In recent years,in European countries have emerged new theories and practics to maintain the balance between on one hand safety and operating performance; and costs and environmental protection on the other.

The project starts with basic research oriented for acquiring new scientific knowledge, formulating and verifying theories and assumptions, based on which the project will be developed. To achieve the objectives, in the first phase of the project is necessary the fundamental research, which is mandatory given the complexity and continuos progress of new knowledge in the field of turbine engines. International reserch is interested in this field and constantly develop new theories and new concepts.

Progress Stage 1

Finished in december 2007

- Study on optimization of the combustion and pellicular cooling.

- Study on possibilities to optimize the functioning of the turbine engine

- Study on heat-resistant coatings

- Studies on the optimization of cycle cogeneration turbine engines. The progress of the sollution used in the world.

- Study of the physico-mechanical performance of materials used for modified parts

- studies and research on the achievement of constructive technological changes

- Study of the physical properties for special coatings.

Dissemination - Articles

- Article: “The optimization of the functioning parameters of mechanical ensembles mode from composite materials” ; Ilie BUTNARIU, Nicolae CONSTANTIN, 9th US National Congress ore Computational Mechanics” , San Francisco, SUA, 22-26 iulie 2007

- Article: “The good using of the Useful Elements from the Copper Removal” , Ilie BUTNARIU, Nicolae CONSTANTIN ; R’ 07 World Congress, Devos, Elvetia, 3-5 september 2007

Stage 2

Based on the fundamental research conducted on the first stage,in the second stage were developed the designing documents for the needed changes and the technological documents to achieve termo-resistant coatings. Also in this stage were realized both, the specific documents for metallurgical-structural control of thermo-resistant coatings for the functional model designed parts; and the metallurgical-structural control methods for the thermo resistant coatings of the functional model.

Progress Stage 2

Finished in decembrie 2008

- Documentation development for the modified components

- Development of metallurgical-structural control specific documentation for thermo-resistent coatings belonging to the functional model.

- Technological design of the experimental model

Dissemination - Articles

- Article: “ The new approach of the maintenance.The analyze of the monitoring, control and check up processes for the functionality of the turbojets ”, Mariana Stefanescu, Constantin Nicolae, Sorin Neacsu; METALURGICA INTERNATIONAL / 2008 /Special Issue no. 3 /ISSN 1582-2214 / EDITURA STIINTIFICA F.M.R

- Article: “ High temperatures, abradability and corrosion new resistant material integrated with original technologies addressed to surface covering of elastic components of gas turbine”, Georgeta Carlanescu, Cristian Puscasu; Mihaela Grigorescu, Constantin Nicolae, METALURGICA INTERNATIONAL / 2008 /Special Issue no. 3 /ISSN 1582-2214 / EDITURA STIINTIFICA F.M.R

- Article: “ EFFECTS OF ADDITIVES ON THE SINTERING PROCESS OF Al2O3-BASED CERAMIC MATERIALS ”, Nicolae CONSTANTIN, Mioara Adriana COMSA , Aurica GOLEANU, Miron BUZDUGA ; al 2-lea Congres International de Ceramica - ICC2, de la Verona-Italia, iunie 2008, ISSN 1843-5904

Stage 3

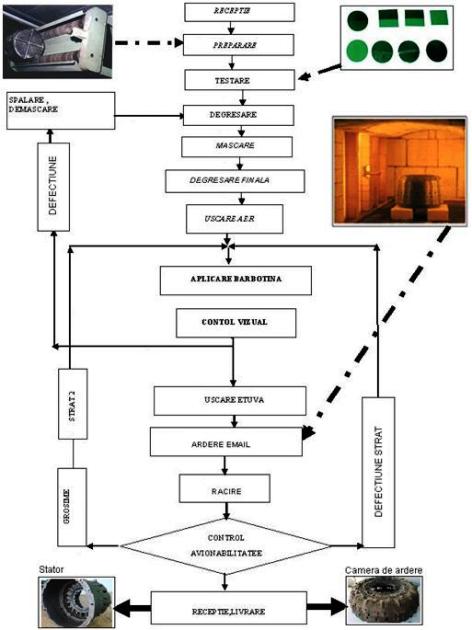

Stage no. 3 „ Realization of the experimental model – first stage” of the project „ Increasing energy’s efficiency in turbine engines by skin cooling and special heat-resistent coatings”, has a special importance in the development of the project, beeing the first in which all the realized researches and studies gets a applied materialization, in clear testing and verification programs for the new adopted solution.

Inside this stage it begins The Realization of the experimental model by solving the problems related to control and testing documentation and by establishing the material and surface coating proper to the given working conditions.

And in this stage we were working effectively in teams, with concrete goals.

All the partners in the consortium have contributed to the realization of the phase,each solving his assumed problems. Project leader, INCDTurboengines COMOTI had the duty to create a unified documentation.

Progress Stage 3

Finished in june 2009

- Development of technical and control documentation necessary to realize the E.M.

- Preliminary tests for characterization of surface coatings

- Analysis and determination of testing technology that must be done

- The structure of materials and types for the surface coatings that will be tested on the E.M.

Stator covered with a layer of protection

Stage 4

Stage no. 4 „ Preliminary technology testing ” of the project „ Increasing energy’s efficiency in turbine engines by skin cooling and special heat-resistent coatings ”, is a normal continuation of stage 3 for realizing of the experimental model. Inside this stage is continued the realization of the experimental model by solving the problems conected to the control and testing of the samples coated with materials resistent to the optimal temperature for the given working conditions.

Progress stage 4

Finished in december 2009

- Preliminary tests in order to achieve the experimental model

- Metallurgical inspection specific documentation

Dissemination - Articles

Article: “ New Procedures and Methods in Chemical Treatment and Centrifugal Separation Field in Wastes Components of Oil Industry” , LIVIU ADAM, CRISTIAN PUSCASU, NICOLAE CONSTANTIN, SORIN NEACSU, MIHAI BUTU, FLORINEL GH. DINU, Chemisty Magazine, volume 2009 , Octombrie

Stage 5

Stage 5 is curently underway, it has the role to close the activity of this project.

Rezultate Etapa 5

Will be finished in november 2010

INCDT COMOTI stand for testing the combustion chamber of turbine engines and other components

|