|

A. To purchase a milling machine with numerical control having the following main features:

-Milling machine with 4-axis numerically controlled simultaneously, and a focus for additional drilling alezare and ordered all numeric - axes X, Y, Z, W, B

- Materials that can be processed: cast iron and steel, aluminum alloys, titanium alloys, alloy steel, stainless steel

- Machine type allows processing carcass parts with maximum dimensions: length 3000 mm x 2000 mm x height 1600 mm width

- Processing that may be performed: milling flat and profiled, lamaje, drilling, alezari, threads

- Curse: X axis: 3000 mm Y axis: 2000 mm Z axis: 1600 mm W-axis: 700 mm

- Advance fast (axes X, Y, Z, W): 10 m / min

- Advance of cutting: 1 - 4000 mm / min

- Distance between axis and axis pincipal the table: 750 - 2350 mm

- Power of the engine main axis (cont. / 30 min): 22 / 26 kW

- Main axis diameter: Ø130 mm

- Diameter of spindle head port: Ø240 mm

- Speed of the axis of rotation: 10 - 2500 rpm

- The torque spindle: 3353.6 N.m

- Inside the cone axis: ISO # 50, 7 / 24

- Rotation table is ordered numerically

- Mass index is the increment of 0.001 degrees

- Presents pin lock every 90 degrees

- Rotary positioning accuracy: ± 15 ˝ (and every 90 degrees ± 5 ˝)

- Table dimensions: 1600 x 1800 mm

- Maximum weight allowance on the vehicle mass: 15,000 kg

- Speed of rotation of the table: 1 rpm

B. Mobile Equipment for lifting loads

Characteristics:

-payload: 2000 kg lifting height: 3000 mm

C. Compressed air installation

Characteristics:

- Flow of air filtered and dried: 1.5 cm / min, pressure max. 10 Barg

D.Improving microclimate conditions

-There is a replacement works access doors, a carpentry, interior compartments for improvements the working conditions

E. Cooling at standard conditions in the CNC machines zone

Cooling was performed at 20 0C of the work area of CNC machines

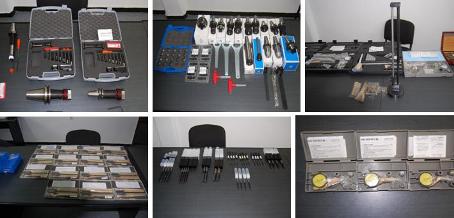

F.Acquisition of equipments for measurement and control and cutting tools

Measurement devices, control devices and various cutting tools have been aquired

|